Firstly, the silver to be soldered must be annealed. This is the initial softening of the silver to be joined; only the areas to be soldered need to be annealed - it is not necessary to anneal the piece as a whole. In order to carry out a successful annealing, use a blowtorch to heat the silver findings, you will need to maintain a constant temperature of around 1200æ F. As the silver findings heat up, they will change colour to a dull-pink - this is the temperature you want to maintain for approximately 30 seconds, and you can do this by gently moving the flame back and forth in accordance with the colour of the metal as it changes.

Once you have checked the parts to be soldered for gaps, you must apply some flux. Flux is a chemical cleaning agent that prevents the silver findings and the solder metal from oxidation. At room temperature, flux is practically inert but, as the temperature rises, it becomes strongly reducing and prevents the formation of metal oxides. It also allows the solder metal to flow easily.

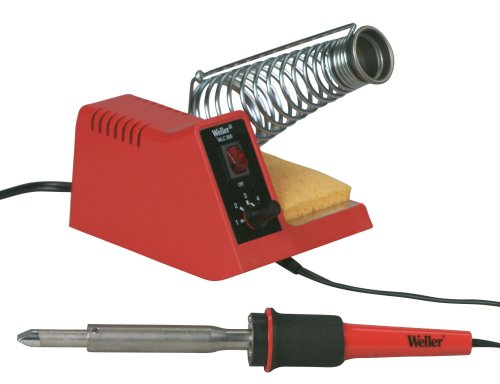

Soldering Supplies

The next stage is to cut and apply a piece of solder. For silver findings, solder metal can come in one of four grades: ex-easy, easy, medium, and hard. Each has its own melting point and different grades can be used in conjunction with one another for complex soldering. However, for silver findings, an easy grade solder is usual. The piece of soldering metal is then placed on or under the join that you wish to make.

The piece now needs to be heated. It is important not to heat the solder directly but, rather, heat the piece as a whole and heat will transfer into the solder material by conductivity. Many artisans use a solder probe or titanium stick for this purpose, allowing them to manipulate the piece and ensure the even spread of heat. The solder will begin to shine and then flow along the joint. It is at this point that the piece can be allowed to cool briefly.

Finally the piece needs to be quenched. This involves dunking the soldered findings into a solution of diluted sulphuric acid, to remove firestain; this solution is known as a pickle. It is best to remove the soldered piece from the pickle with a pair of brass, plastic or even copper tongs, as these are unlikely to contaminate the solution. The piece can then be washed in water. Once the piece is dry you can then begin polishing.

Click for larger image and other views

Weller WLC200 80-Watt Stained Glass Soldering Station Feature

- On/Off switch with "power-on" indicator light.

- Variable power control produces 5-80-Watt.

- Quality lightweight pencil iron with cushioned foam grip with replaceable heating element.

- Operates with MTG20, MTG21 and MTG22 tips.

- UL listed.

Weller WLC200 80-Watt Stained Glass Soldering Station Overview

Wattage 5 W - 40 W

Temperature Range 900° F

Voltage Input/Output 120 V/120 V

Temperature Accuracy Not Measured

SAVE NOW on the special offers below!

Available In Stock. |

| This Weller WLC200 80-Watt Stained Glass Soldering Station ships for FREE with Super Saver Shipping. |

Price : Click to Check Update Prices Please. |